Contact: Liselot Goris, Start Date: March 2026

The stapes bone is the smallest bone in the human body, measuring 2 to 3 mm, and it is part of the ossicles in the middle ear. This stirrup-shaped bone transmits sound vibrations from the incus to the inner ear via the oval window. Damage to the stapes, such as from otosclerosis (abnormal bone growth), can impair hearing and may lead to hearing loss (HL). To treat HL, a prosthesis can be inserted surgically. The most common cause of recurrent conductive HL after surgery is prosthesis displacement [1].

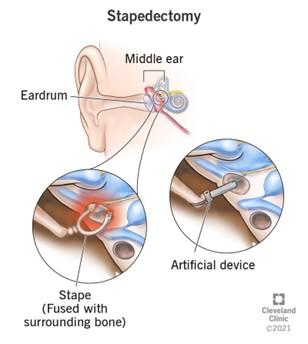

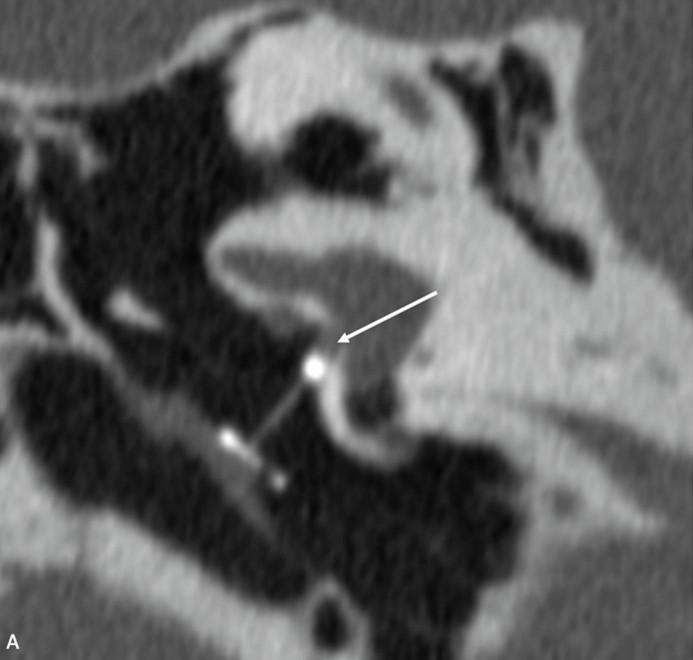

Figure 1: Stapedectomy surgery [3] (top image) and CT image of the stapes bone with artificial device (arrow points towards the outer tip of the prosthesis) [1] (bottom image).

Figure 1: Stapedectomy surgery [3] (top image) and CT image of the stapes bone with artificial device (arrow points towards the outer tip of the prosthesis) [1] (bottom image).

High-resolution CT can detect prosthesis dislocation and displacement outside the oval window but may be nondiagnostic in up to 78% of cases of recurrent conductive HL. Vertigo is observed in up to 60% of patients during the immediate postoperative period. Mild symptoms usually resolve with conservative treatment, while severe cochleovestibular dysfunction may necessitate revision surgery. Therefore, measuring prosthetic intrusion into the vestibule remains critical. However, modern temporal bone imaging systems with 0.5 mm slice thickness are reportedly not yet able to depict the stapes piston position with sufficient accuracy. [1,2]

Ultra-high-resolution photon-counting CT (PCCT) offers improved spatial resolution and may enable the accurate and precise imaging of the stapes bones. [4,5] To test the accuracy and precision of this PCCT for measuring the position and size of the stapes bone, phantom studies can be conducted.

The goal of this project is to 3D print an anthropomorphic head phantom of the inner ear, including the ossicles (and thus, the stapes bone), to test the accuracy and precision of the new PCCT for measuring the stapes sizes and position.

The phantom will be printed using a Bambulab FDM printer with different materials for the structures in the head and inner ear. During the project, you will characterise different materials and determine the most suitable ones for the bones and soft tissue. [6-8] Furthermore, you will segment patient images for the design of the phantom. Once the phantom is printed, you will perform tests on the PCCT system to determine the accuracy and precision. Optionally, you could look into optimisation of the imaging protocol.

This is a hands-on project that involves working with a state-of-the-art imaging system and innovative 3D printing techniques.

More on the information contact: Liselot Goris,

This project is based at the University of Twente’s multi-modality medical imaging group (M3I). PCCT measurements will be conducted at Radboud University Medical Centre.

The project duration is 6-9 months.

[3] Stapedectomy: Definition, Surgery, Procedure & Recovery

[4] Photon Counting CT | CT | Canon Medical Systems

[5] Clinical Research on Photon-Counting CT Begins with Radboud University Medical Center

[7] Dual-energy CT evaluation of 3D printed materials for radiotherapy applications - IOPscience

[8] A filament 3D printing approach for CT-compatible bone tissues replication - ScienceDirect